Aluminum Foundry expertise that guarantees superior product quality

Wiki Article

The Function of Aluminum Foundries beforehand Lightweight Production Solutions

Light weight aluminum foundries significantly add to the development of light-weight manufacturing services. Their ingenious casting technologies produce high-strength, light-weight parts vital for markets like automobile and aerospace. This innovation not only boosts item efficiency but also promotes sustainability via the use of recycled products. As these shops adapt to arising innovations and methods, they lead the means for future advancements in producing effectiveness and ecological obligation. What exists ahead in this transformative journey?The Advantages of Lightweight Materials in Manufacturing

As industries increasingly seek effectiveness and sustainability, the adoption of lightweight materials in manufacturing has become an important strategy - Precision aluminum casting. These products, particularly aluminum and composites, provide various advantages that boost production procedures and item performance. Primarily, their minimized weight adds to lower energy intake throughout transportation and procedure, bring about significant expense financial savingsLight-weight products assist in the style of more complicated geometries, permitting for greater technology in product development. This flexibility frequently results in boosted capability and performance, providing to the evolving needs of contemporary consumers.

Additionally, the usage of lightweight products can improve the long life of items because of their resistance to deterioration and fatigue. This resilience not just reduces maintenance prices yet also sustains sustainability efforts, as longer-lasting products contribute to much less waste. To sum up, the benefits of light-weight products are crucial in driving efficiency, advancement, and ecological duty in manufacturing.

Innovations in Aluminum Spreading Technologies

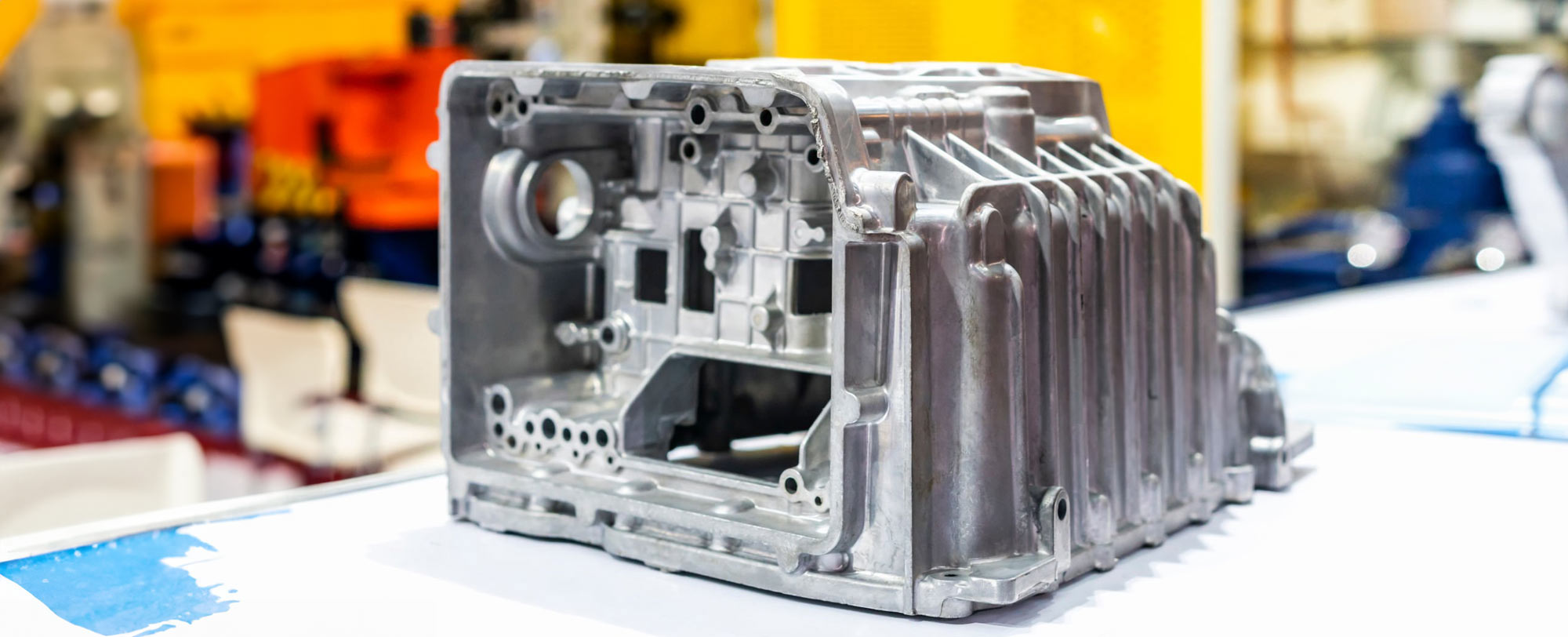

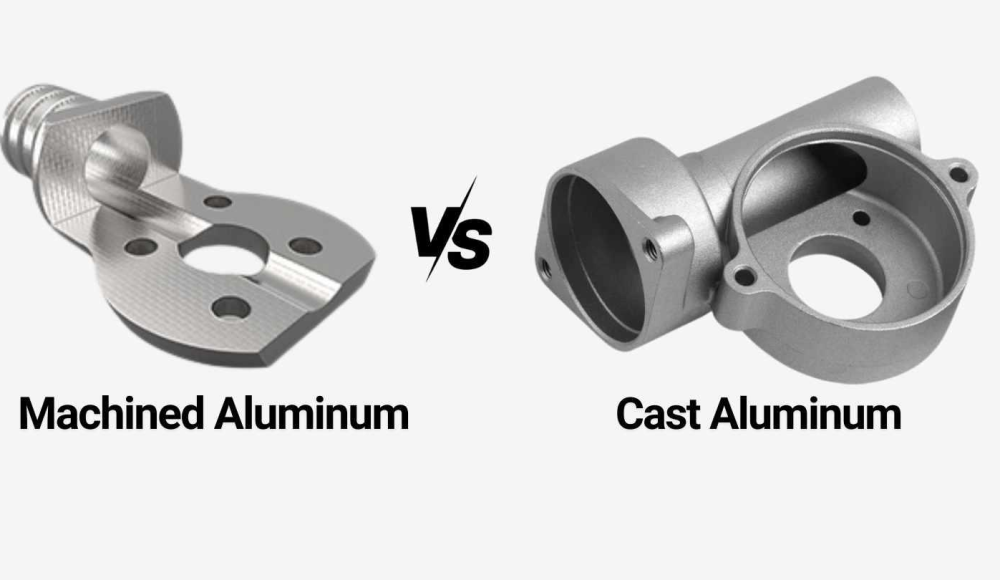

Recent developments in aluminum casting innovations are transforming the manufacturing landscape, particularly in the production of light-weight elements. Innovations such as high-pressure die spreading and vacuum cleaner pass away casting have actually considerably enhanced the accuracy and surface area finish of light weight aluminum parts - Aluminum Casting Company. These techniques permit for the creation of complex geometries while lessening material waste and improving mechanical buildings

Additionally, the implementation of real-time surveillance systems assures quality assurance throughout the spreading procedure, leading to more regular product outcomes. Jointly, these developments not just enhance the performance of light weight aluminum parts but also support the sector's shift in the direction of more sustainable production methods.

Applications of Aluminum Components in Various Industries

While light weight aluminum parts have long been made use of in numerous sectors, their adaptability and light-weight buildings proceed to drive innovative applications throughout fields such as automobile, aerospace, and construction. In the auto sector, light weight aluminum is progressively utilized for engine blocks, wheels, and body panels, enhancing fuel efficiency and performance. Aerospace suppliers leverage aluminum for airplane frameworks and components, utilizing on its strength-to-weight ratio to boost fuel economic situation and payload capacity.In the building sector, light weight aluminum is favored for window structures, roof covering, and architectural components, supplying longevity and resistance to deterioration while minimizing overall building weight. Furthermore, the electrical and electronics industries gain from light weight aluminum's conductivity and lightweight nature, using it in circuitry, rooms, and warm sinks. These varied applications highlight the important duty of aluminum components, which not just satisfy industry needs yet likewise add to innovations in product style and capability throughout numerous areas.

Sustainability and Power Performance in Light Weight Aluminum Foundries

The light weight aluminum shop sector plays a crucial role in advertising sustainability and power efficiency, especially as need for lightweight elements remains to grow across different markets. Factories are progressively adopting eco-friendly techniques, such as using recycled aluminum, which considerably reduces power usage and greenhouse gas exhausts contrasted to key aluminum production.Moreover, innovations in casting technologies improve energy performance by maximizing the melting processes and decreasing waste. Techniques like die spreading and investment spreading enable for specific material use, reducing excess and scrap.

In addition, numerous shops are buying eco-friendly energy resources to power operations, further reducing their carbon impact. Implementing power management systems enables factories to keep an eye on and enhance energy use, guaranteeing they run at peak efficiency.

Future Trends in Lightweight Manufacturing Solutions

Exactly how will arising technologies shape the future of light-weight manufacturing options? Technologies such as innovative products, automation, and additive production are established to redefine manufacturing processes. The integration of smart manufacturing technologies, including the Web of Points (IoT) and expert system (AI), will enable real-time monitoring and optimization, enhancing efficiency and reducing waste.

As sustainability continues to be a paramount problem, lightweight solutions will significantly focus on recycling and recycling materials, lining up with circular economy concepts. This evolution in light-weight manufacturing will certainly not only boost product efficiency but additionally add to ecological goals, making certain that the industry continues to be competitive in a swiftly altering market landscape.

Frequently Asked Inquiries

Exactly How Do Light Weight Aluminum Foundries Ensure Quality Assurance in Manufacturing?

Aluminum shops assure top quality control in manufacturing via rigorous testing, standardized treatments, and continual monitoring - Aluminum Foundry. They carry out competent employees and advanced innovations to keep uniformity, decrease flaws, and meet market requirements throughout the production processWhat Are the Main Tests Encountered by Aluminum Foundries?

Aluminum factories encounter challenges such as varying basic material costs, maintaining production efficiency, making certain consistent quality, adapting to technological developments, and meeting environmental guidelines, all of which effect their general functional performance and competition in the aluminum casting market.How Does Aluminum Recycling Influence Shop Procedures?

Light weight aluminum reusing substantially boosts shop procedures by lowering basic material prices, minimizing power intake, and decreasing environmental impact. This sustainable practice enables foundries to improve performance while meeting raising demand for lightweight, high-performance aluminum products.What Abilities Are Required for Employees in Aluminum Foundries?

Employees in aluminum foundries require abilities in metallurgy, machining, top quality control, and safety and security methods. Efficiency in operating machinery, recognizing alloy buildings, and analytic are likewise important for efficient manufacturing and preserving high safety standards.Just How Do Aluminum Foundries Handle Waste Management?

Light weight aluminum shops manage waste via recycling scrap steel, using efficient waste partition techniques, and adhering to environmental laws. They carry out sustainable practices to decrease garbage dump contributions, ensuring that harmful materials are disposed of sensibly.Aluminum factories greatly add to the evolution of light-weight manufacturing remedies. Recent innovations in aluminum spreading technologies are reinventing the manufacturing landscape, especially in the manufacturing of light-weight components. While light weight aluminum parts have long been used in numerous sectors, their flexibility and light-weight buildings proceed to drive cutting-edge applications across sectors such as automobile, aerospace, and construction. Additionally, the electrical and electronic devices sectors profit from light weight aluminum's conductivity and light-weight nature, utilizing it in circuitry, enclosures, and heat sinks. The aluminum foundry market plays a critical role in promoting sustainability and energy efficiency, especially as demand for lightweight components continues to grow across various industries.

Report this wiki page